The Application of Machine Vision for AOI System

AOI is the full name of Automatic Optical Inspection, is based on the optical principle of welding production encountered common defects to detect equipment. AOI is a newly emerging test technology, but the rapid development of many manufacturers have introduced AOI test equipment. When automatic detection, the machine through the camera automatically scan the PCB, the acquisition of images, test the welding spot and the database of qualified parameters are compared, after image processing, check out the defects on the PCB, and through the display or automatic marking defect display / label Come out for maintenance personnel dressing.

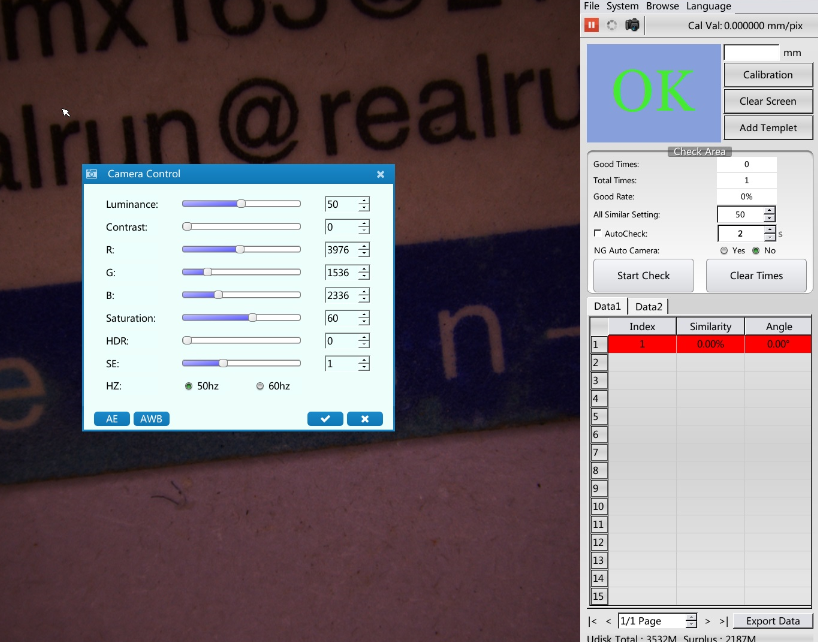

AOI system usually use industrial cameras with Bi-telecentric lenses, and some high flex towline cables (drag chain system) to connect the industrial cameras to the computer or monitor. With the ability of the software in the computer or the industrial cameras, AOI system can use the image processing technology to detect foreign matter or pattern defects and other defects, because it is non-contact inspection, so you can check in the intermediate engineering semi-finished products. High-precision optical image detection system, including measuring lens technology, optical lighting technology, positioning measurement technology, electronic circuit testing technology, image processing technology and automation technology applications and other fields, the development and application of high-tech industries not only meet the development needs of its technology The level can be extended to the defense industry, military weapons manufacturing, night vision combat system, strategic topography analysis and evaluation, are closely related with this imaging technology.

Donghoo Technology is a company that mainly manufacture high flex towline cables for industrial cameras, such as Basler cameras, Cognex cameras, Baumer cameras, Teledyne DALSA cameras and so on. We offer OEM/ODM services, and the cables can be customizied as you wish.